Cracked Glass Tile Mosaics - The Flaws Within!

By Paolo Benedetti, SATURDAY, JANUARY 30, 2010

Internationally renown designer, consultant, contractor & expert witness Paolo (Paul) Benedetti offers his opinion as to why many manufacturer's product lines of glass tile mosaics crack. Paolo precisely follows the Tile Counsel of North America (TCNA) and American National Standards Institute (ANSI) installation guidelines & recommendations. Yet, he has had projects where the glass tile mosaics cracked randomly, throughout the installed field in no pattern, & for no apparent reason. He has inspected the work of others, when they also experienced unexplained random cracking & fissures. He has almost 20 years of experience creating spectacular glass tile mosaic knife edge perimeter overflow pools, spas, waterfalls, and water features, infinity edge pools, vanishing edge pools, disappearing edge pools, negative edge pools, no coping pools, zero edge pools, no edge pools, and edgeless pools.

Internationally renown designer, consultant, contractor & expert witness Paolo (Paul) Benedetti offers his opinion as to why many manufacturer's product lines of glass tile mosaics crack. Paolo precisely follows the Tile Counsel of North America (TCNA) and American National Standards Institute (ANSI) installation guidelines & recommendations. Yet, he has had projects where the glass tile mosaics cracked randomly, throughout the installed field in no pattern, & for no apparent reason. He has inspected the work of others, when they also experienced unexplained random cracking & fissures. He has almost 20 years of experience creating spectacular glass tile mosaic knife edge perimeter overflow pools, spas, waterfalls, and water features, infinity edge pools, vanishing edge pools, disappearing edge pools, negative edge pools, no coping pools, zero edge pools, no edge pools, and edgeless pools.

The Flaw's Lies Within... the Naked Truth!

Internal stresses within glass tiles, lie invisible to the naked eye. A tile that looks perfect & unblemished to the unassisted eye, may actually contain inherent stresses that may later manifest themselves as cracks, fissures, or degradation. I have seen these manifest themselves in the manufacturer's very own sample boards and even in unmounted and uninstalled tiles!

For years, the manufacturers have blamed the installers. Why? Because it is very easy to find where the installers deviated even the slightest from the installation instructions. Once there is a crack in that armor, they'll drive a truck through. The suspicion instantly shifts from the possibility of faulty tile, immediately to incorrect installation practices & materials.

Glass tile manufacturers deny that their glass tiles possess any internal stresses. Of course, who in the world would expect them to say, "Golly jeepers, you got us. We really sell an inferior product that possesses inherent invisible internal flaws that will manifest themselves after the tiles are installed." The quote you'll hear is, "they were inspected before they left the factory," or "they weren't cracked when they left the factory."

But, were they really truly inspected? Of course not! Actually, most of the glass tile manufacturers do not even bother to inspect for internal flaws!

Why? Because they are too ignorant (and do not want to know the truth) or they have too much money at stake. Imagine the lost profit, good will, consumer faith, and liability for all of their past inferior production, if they admitted that their products were inherently defective?! Or they are attempting to "compartmentalize" each case of failure, in an attempt to prevent the consumers, government, or attorneys from collectively getting smart & sharing information, and thereby realizing that they're not the only ones who are experiencing this problem (as the manufacturer's will lead you to believe).

If the glass tile manufacturers can keep we as the end users, constantly seeking absolute perfection in our installation procedures, then they will surely take that stance! There are just too many small variables present between different jobsites, applications, & installations to achieve continuity in the installations. The results are that this material seems to be so fragile & delicate - which it is not!

The technical service staff or production managers at most of these firms have not even been provided with the information, training, nor the apparatus to perform the simplest of these inspections. They are simply not aware that the product that they selling is actually flawed!

Like cancer, it's what you cannot see that will hurt you!

So like cancer, in order to detect it early, you need to get "regular screenings." How does this apply to glass tile?

Simple - buy yourself a POLARISCOPE! A what-scope? It sounds expensive!! Well, in actuality they are not - ranging from $250-$1500. The attached images were taken with a hand held digital camera and a $500 polariscope. Many of the manufacturer's do not know what a polariscope is, let alone even own a polariscope. So how do they perform inspections for internal flaws? Simply stated... they don't!

Scary, isn't it?! Once the tiles crack in the field, they get to blame YOU or your installation practices. As their taillights fade in the distance you'll hear, "the tiles did not leave the factory cracked!"

How does a polariscope work? A polariscope is a simple light box, with 2 polarizing filters. The tile to be inspected is laid upon the light table, and the viewer looks through the 2 polarizing filters. These filters polarize & align the planes of light. One of the filters is rotated (or the sample is rotated) to highlight any stresses. As the light passes through the transparent material (in this case glass tiles), the light becomes retarded by any inherent flaws. The more retarded the light, the more stress in the material and the brighter the highlighting. The stress appears as a white "hot spot" within the image.

Some manufactured glass tiles have small surface blemishes (wrinkles, scratches, or chips) that the manufacturer's claim is a part of their "character & uniqueness," when these in fact can impart stresses onto/into the glass tiles. An example of this is when a glaziers scribe (rolling carbide glass cutter) is ran across the surface of a glass tile. Once scribed, that "scratch" actually imparts "stress" into the glass tile... stresses that the glazier actually relies upon in order to crack a sheet of glass in a straight line. The bottom line, is that surface flaws can (but not always) cause stresses within the tiles. Some tiles are manufactured with wrinkles and textures that do not impart any stresses - the buyers & end users need to be informed! The only way to know for sure, is to use a polariscope.

Wait a minute, how can this simple test be so informative? Is it valid? Well the US Food & Drug Administration uses this very device & a technique to inspect glass drink and food containers. This link also explains in greater scientific detail how the polariscope works:

http://www.fda.gov/ICECI/Inspections/InspectionGuides/ucm071623.htm

So from now on, when the manufacturer's information says that it is, "the users responsibility to inspect the tiles & verify that the tiles are suitable for the intended purpose," you have a simple apparatus to perform such inspection quickly & inexpensively. By the way, such a warranty disclaimer clause is illegal in California, outlawed in the CALIFORNIA CIVIL CODE SECTIONS 1792-1795.8.

I am not promoting any particular brands of tiles here. I know from firsthand experience that the following manufacturers perform routine random sample testing & observations of their glass tiles. I also have not experienced or observed any major failure issues with any of the following brands (listed in no particular order)*:

http://lightstreamsglasstile.com

http://www.sicis.it

http://www.bisazza.com/usa/

http://www.kolorines.com/

http://www.interstyle.ca/

*Just because a particular brand of glass tile is not listed above, does not not mean that they are not performing these inspections or are having internal stress issues (no, that doesn't mean they've missing their morning cup of coffee). It just means that I do not have any personal knowledge or experience to speak firsthand as to the quality of their products or production process. I am not opposed to accepting a fully paid facilities inspection tour or to accepting material samples to "field test," from any manufacturer's that are not listed. Regardless, I will continue to independently report my field observations & firsthand experiences!

Lest I remind you, that these observations apply to glass tiles - not porcelain or ceramic!

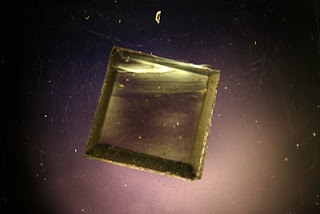

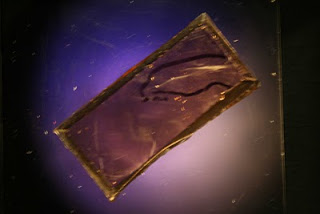

Maybe these flaws are so small, that they are merely slipping through the manufacturing process...?? Hardly... for example, my 10 year old son sorted & picked out the attached tiles (which I photographed) and attached as examples. The small white specs throughout the images are speckles of dust on the lightbox surface.

In the following images internal stresses (seen as white hot spots, streaks & clouding) are clearly visible within the tiles :

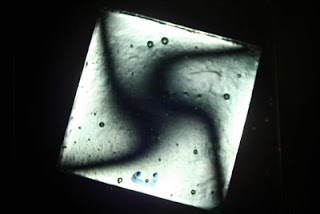

The swirling star that is observed in the following image, is what an acceptable tile looks like. The bubbles within the glass tile, do not inherently create stress or weaknesses. You can clearly see that there are no observable stresses surrounding the bubbles.

NOW YOU CAN "SEE..."

...that the flaws may actually lie within, and not with the end user or installer!